An Essential Guide To Asphalt

One of the most versatile construction materials, you’ll be more familiar with asphalt than you realise having likely driven, played, exercised, cycled or even landed in a plane on it. Most well-known as the predominant material for road construction, asphalt has a variety of uses and is durable, sustainable and flexible. Our guide reveals all you need to know about this popular product…

Summary of key points:

- Asphalt is a composite material used for various construction applications, including road construction (95% of UK roads)

- Made of aggregates (crushed stone, sand, gravel) and bitumen (viscous and waterproof substance)

- Types of asphalt include: Asphalt Concretes, Hot Rolled Asphalts, Stone Mastic Asphalts Asphalt differs from tarmac, which was made of aggregates and tar (no longer used due to its carcinogenic properties)

- Asphalt is popular for road construction due to: being cost-effective, low maintenance, durable, fast to construct, able to withstand weight/temperature fluctuations, easy to maintain/repair, producing a smooth surface, reducing noise pollution, improving visibility for drivers

- Asphalt production is moving towards being more sustainable and environmentally-friendly, using recycled materials and reducing carbon footprint through production methods (Hot Mix Asphalt, Warm Mix Asphalt, Cold Mix Asphalt).

What is asphalt?

Asphalt is a composite material that is used worldwide for construction, infrastructure, recreation, aviation, agriculture and industrial applications. Typically black, although available in coloured varieties too, asphalt is manufactured in a plant and becomes a hard surface when it cools to an ambient temperature. The UK produces approximately 25 million tonnes of asphalt annually and accounts for over 95% of our roads.

What is it used for?

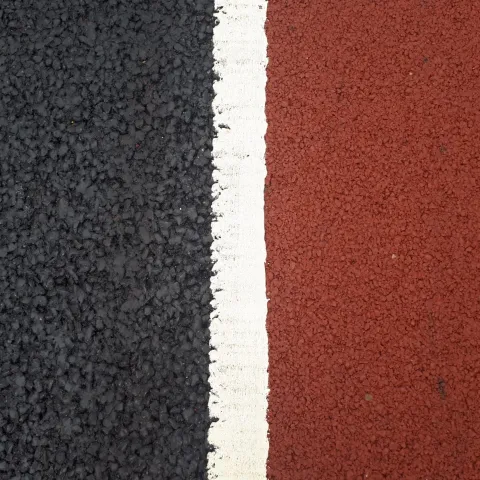

The primary use for asphalt is the construction of roads and highways, including bus and cycle lanes, airport runways and taxiways, footpaths and pavements. Its versatility means it is also used for car parks, playgrounds, driveways, construction and agricultural flooring, sports surfaces such as running tracks or tennis courts, and motor racing circuits.

What is asphalt made of?

Asphalt is a composite material with two primary ingredients: aggregates and bitumen. Aggregates – usually crushed stone, sand and gravel – are bound together with bitumen (a viscous and waterproof substance) at high temperature to become asphalt.

- There are up to three layers of asphalt in the typical construction of a pavement.

The lower layer is the base which sits on top of a sub-base and provides the main load-bearing for the road. - The layer above is binder course, approximately 50-90mm thick, which is a load bearing layer designed to distribute the load from the surfacing into the base course thus avoiding deformation. It is also used as a levelling course.

- The uppermost layer is the surface course, which is approximately 25-50mm thick and provides an even, skid-resistant and waterproof surface

Typically, the aggregate size decreases as you move up through the construction from the base to the surface course, whilst the bitumen content increases.

The different types of asphalt

Depending on the application, asphalt is designed to achieve varied strength and flexibility. While there are seven general asphalt mixture types in total, there are three common asphalt groups used in the UK which form 95% of the product we produce. These are:

Asphalt Concretes (ACs)

In this asphalt, aggregate particles are continuously graded to form an interlocking structure bound together with bitumen.

Hot Rolled Asphalts (HRAs)

A dense, gap-graded bituminous mixture in which the mortar of fine aggregate, filler and high viscosity binder are major contributors to the final performance of the laid material.

Stone Mastic Asphalts (SMAs)

Gap-graded asphalt mixture, composed of a blend of single size coarse crushed aggregate forming a stone skeleton bound with high contents of bitumen.

What is the difference between asphalt and tarmac?

These are colloquial terms for essentially the same product. Back in time when tar was produced as a bi-product of coke production, tar was the primary binding agent for asphalt mixtures. Since the association of tar as a potential carcinogenic substance, bitumen derived from oil distillation has become the default binder type and they have very similar appearance and properties. Since the late 1980s and early 1990s, tar has ceased to be used in the production of asphalt, as it is considered hazardous.

Why do we use asphalt for roads?

Asphalt is cost-effective, low maintenance and extremely durable, making it an ideal road surfacing material. It is a popular choice because:

- It is fast to construct

- It can withstand significant weight and temperature fluctuations

- It is easy to maintain and repair

- It produces a smooth surface for maximum tire grip

- It reduces noise pollution

- It rapidly disperses surface water, reducing spray, the risk of aquaplaning and improving visibility for drivers

- It increases the visibility of road markings

Is asphalt sustainable and can it be recycled?

As we collectively move towards Net Zero, the production of asphalt has evolved to adopt greener techniques for production. Asphalt is one of the most sustainable construction materials, as we can use construction waste and recycled asphalt planing (known as RAP - whereby the recycled road surface is put back into the production process) as replacement aggregates. This is effectively put into practice throughout the road construction industry.We also optimise the use of RAP in new cold asphalt innovations such as our Foamix® range.

We can also adapt the manufacturing method to reduce the carbon footprint of the product, and therefore the entire project. There are three key production methods:

Hot Mix Asphalt (HMA)

HMA is traditionally made at a high temperature ranging between 140-190⁰C.

Warm Mix Asphalt (WMA)

Mixed at temperatures 20° to 40°C lower than HMA, Warm Mix Asphalt is the greener choice as it requires significantly less energy during manufacturing and therefore releases less emissions. WMA is also considered safer for construction crews as the temperature of the material is lower and it thereby emits minimal odour and steam. All of our WMA are tested to meet industry specifications and are suitable for the same applications as HMAs, without compromising performance.

Cold Mix Asphalt (CMA)

Most useful for repairs and maintenance of small cracks, potholes or patching of existing pavements, Cold Mix Asphalt is produced without any heat and, instead, water is used for emulsification.

To go one step further, we’ve also developed other ways to reduce embodied carbon during the manufacturing process and have launched our SuperLow-Carbon range, which includes a biogenic substitution within the bitumen that effectively locks carbon within the asphalt.

CONCLUSION

Asphalt is one of the most widely used, reliable products with a virtually unparalleled versatility when it comes to road surfacing, commercial and domestic applications. View our full range of nearly 30 asphalt products here.

Frequently Asked Questions

Today's asphalt can be 100% recycled back into new asphalt. Asphalt produced with tar is now classified as a hazardous waste and when it is identified and recovered cannot be recycled back into hot asphalt, but instead is contained and bound in cement or reserved only for cold asphalt production.

No, bitumen is the binding agent for asphalt. (Except in the USA where the term asphalt is used primarily to describe the bitumen).

Concrete is a stiffer mix with less flexibility, but it is more prone to cracking than asphalt. Asphalt is also more flexible, skid resistant, quiet, cost-effective and quicker to install, but all depends on the intended application.

Warm mix asphalt is a more sustainable solution for infrastructure applications, requiring less energy to produce, meaning significant carbon savings can be achieved. Warm mix asphalt performs the same as its hot mix counterpart and is considered the future of roads.

Yes, coloured asphalt such as SuperColour Ultra or SuperRed is used frequently, from creating amazing playground surfaces for children to demarcation for cycleways, bus lanes and residential roads, as well as places requiring additional safety, i.e. nearby to schools.