ECOPact - The LOW CARBON CONCRETE RANGE

WE NEED TO MAKE A PACT... It’s the only way we can build progress for people and the planet together.

ECOPact is the world’s broadest range of low-carbon concrete.

It offers up to significantly lower emissions of CO2 emissions compared to standard (CEM I) concrete with no compromise on performance.

ECOPact is the innovative approach that we have developed at Holcim and Aggregate Industries to accelerate the transition to a net-zero future. We can only do this for the future of our planet if we engage with a plan for net-zero in the construction sector.

At Aggregate Industries we have detailed our approach to drive the sustainability agenda with transparency of data, targets and objectives to achieve in the UK outlined in our sustainability strategy. We are committed to help you, our customers reduce the footprint of buildings and infrastructure to build better and more with less.

With ECOPact you can:

- Easily reduce the environmental impact of your project with no compromise on performance

- Achieve embodied carbon reduction without the use of offsets

- Contribute to a circular economy by diverting waste from landfill and closing material cycles

- Get green building certifications

- Maintain product strength and quality

- Have a wide range of mixes available for different strengths and applications

- Place, pump and finish like conventional concrete

We are constantly investing in research and development so that we can evolve our ECOPact solutions for customers and reduce carbon by looking at alternative replacement cemetitious materials.

ECOPact And ECOPlanet

Our ECOPlanet green cement range reduces CO2 emissions by at least 30% when compared to standard CEM I cements.

Multi Component mixes

We have invested in a new multi componant range of concrete mixes into the ECOPact solution offer.

Extensively developed and tested through our concrete labs and trials, we can offer customers alternativesmixes according to the new BS8500 standard.

ECOPact and Concrete Demolition Materials (CDM)

To build new from the old, our processes allow us to recycle construction and demolition materials into new building solutions. This is enabled by efficiently distributing, processing, grinding and recycling construction and demolition materials into new building solutions with no compromise on performance. By combining CDM with ECOPact, we not only mitigate carbon emissions but also promote a holistic, circular economy within the construction industry, ultimately advancing us closer to our net-zero emissions goals while fostering sustainability and resilience in the built environment.

At Aggregate Industries, we are committed to helping our customers take the guess work out of carbon calculations for construction with a data driven approach.

We have invested significantly in third party accredited EPDs and carbon reporting methodology with Circular Ecology so we can pass on this vital data to our customers for their projects, helping them to specify sustainably and move towards net zero.

What we can offer:

Project Specific EPD’s

All carbon data uploaded to software platform

On Demand, accurate and transparent data at our fingertips

EPD per mix, per load

PRODUCT AND PLANT ECOPact EPDS FOR LONDON

An industry first for readymix concrete. Product and plant specific EPD independently verified certification not based on averages now available in London.

ECOPact Product Line and CO2 Emission Factors Updated, Enhancing Sustainability and Data Transparency Commitment

The ECOPact range has evolved to incorporate broader sustainable concrete solutions. We have reinforced transparency with updated CO2 factors for GGBS and PFA.

The strategic adjustments align with industry standards and market demands, ensuring continued leadership in sustainable construction practices.

This update aligns with the recent revisions to BS8500 and allows us to offer a broader range of sustainable concrete solutions.

These changes will be reflected in our Environmental Product Declarations (EPDs) and internal carbon tools, ensuring that our stakeholders have access to the most up-to-date and accurate information regarding the environmental impact of our concrete products.

We remain dedicated to advancing sustainability within our industry as we are committed to share transparent and accurate data to support the decarbonisation of our sector.

Read the full details of the changes using the link above.

Download ECOPact Brochure:

GREENER CONSTRUCTION STARTS WITH ECOPact

Concrete is the second most widely used material worldwide, after water. The environmental impact of concrete is not purely due to the per kg carbon produced when compared to other construction materials, it’s due to the sheer volume produced.

Cement, a key ingredient of concrete, equates to 90% of its carbon footprint. Originally this was reliant on using fossil fuels during the manufacturing process. However, did you know this process produces less than 1.5% of UK carbon emissions against an average of 7% worldwide?

As the industry moves away from fossil fuels, we’re actively seeking greener solutions to help decarbonise our environment and achieve the net zero target.

ECOPact is the start, actively reducing CO2 in your build, no matter what the project.

All alongside maximising alternative fuels throughout the production process within both our cement plants. And investing in future technology

to increase our thermal substitution rate at our plants.

Reduced C02

ECOPact range is the industry’s broadest offering of green concrete for sustainable and low carbon construction.

The product is sold at a range of low-carbon levels from 30%-100% lower embedded carbon compared to standard (CEM I) concrete.

Carbon reduction figures are based on industry base levels. For project specific calculations, please contact our technical teams.

100% PERFORMANCE: SUSTAINABLE DOESN’T MEAN COMPROMISE

SAME GREAT DURABILITY

Concrete is durable like no other building material. Buildings erected today stand the test of time for generations. And when a concrete building is torn down, it’s components can be almost completely recycled.

SAME GREAT STRENGTH

A key characteristic of concrete is strength. There’s a myriad of concrete mix possibilities, each designed specifically to meet a range of criteria. This doesn’t have to change with low carbon concrete. You can still create complex designs with the same reliability and strength of traditional concrete.

SAME GREAT FINISH

Whether it’s exploring different mix designs, product proposals or strength testing for added peace of mind, our concrete team is on-hand to help you choose the most sustainable option for your needs.

If you’re looking for the highest performance with the lowest carbon, ECOPact Prime AS concrete increases cement substitution and keeps pace with construction.

The ECOPact range

ECOPact - OVER 30% CARBON REDUCTION

A low carbon concrete utilising blended cement, which has over 30% CO2 reduction compared to a standard concrete (CEMI) mix.

NEW ECOPACT PRIME AS - OVER 50% CARBON REDUCTION - PRODUCT INNOVATION OF THE YEAR 2023 - edie AWARDS

A unique mix, producing a concrete that has greater carbon reduction than ECOPact, plus active strength development and the same setting time as ECOPact. Providing very low carbon concrete with the highest performance.

We can also offer low carbon concrete for key product applications as part of our ECO label range.

What does ECO label mean?

It means that the following concrete speacialist application mixes have been assessed using the same EPD methodology to collect product carbon data which is also verified by third-party Circular Ecology. This process demonstrates that they achieve a minimum of 30% reduction in carbon compared to a standard mix using CEMI.

Agilia ECO - Free-flowing self-compacting concrete.

Artevia ECO - Coloured ready-mixed concretes that are suitable for a wide variety of architectural and decorative applications.

Highpave ECO - Fibre reinforced pavement grade ready-mixed concrete.

Watertight ECO - Specialised ready-mixed concrete, designed to protect a structure from water ingress or to retain water within a structure.

APPLICATIONS

ECOPact mix designs can be used in a variety of structural components: from foundations, columns and beams, to walls, driveways and walkways.

It can be easily handled, pumped and finished like conventional concrete. Our range of ECOPact products have been designed to offer alternative solutions for all construction applications - from structural and infrastructure.

ECOPACT PRIME AS

Developed through extensive product research, this innovative solution offers greater carbon reduction compared to ECOPact, with the same setting time, plus an active development of strength.

ECOPact Prime AS is the UK’s first concrete to offer high levels of carbon reduction without compromising on performance.

- Increases cement substitution.

- Includes advanced technologies to secure the build performance of regular concrete.

- Ensures reduced bleed, high early age strength and improved concrete durability.

- Meets all the existing standards for regular concrete and the design of concrete structures.

- Bespoke mixes can be developed to meet specific site needs.

- Readily available throughout the UK.

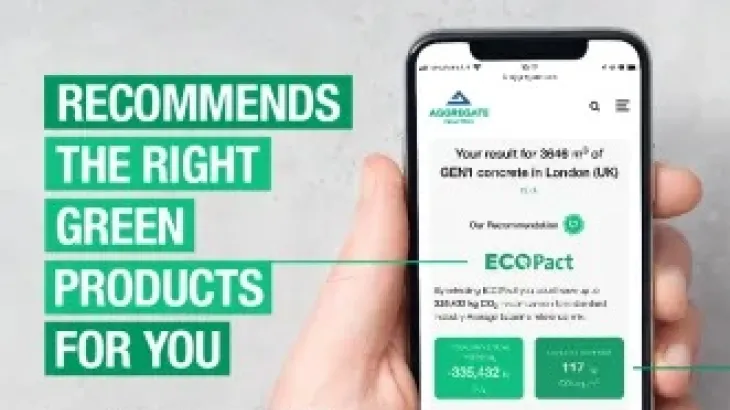

We have an online calculator tool that you can use now! Try today - and see how much carbon you will make by building better with ECOPact.

If you need specific carbon data, we have a dedicated ECOPact team that can provide you with comprehensive carbon calculations, certified by the Carbon Trust and Circular Ecology.

We also have the industry first for readymix concrete, with the first series of Product and Plant specific EPDs for every London Concrete plant that are not based on regional averages. A key step forward in data transparency.

Please contact the team for more information, ecopact-aiuk@aggregate.com.