new SuperLow-Carbon biogenic asphalt for A590 Cross-A-Moor highway scheme

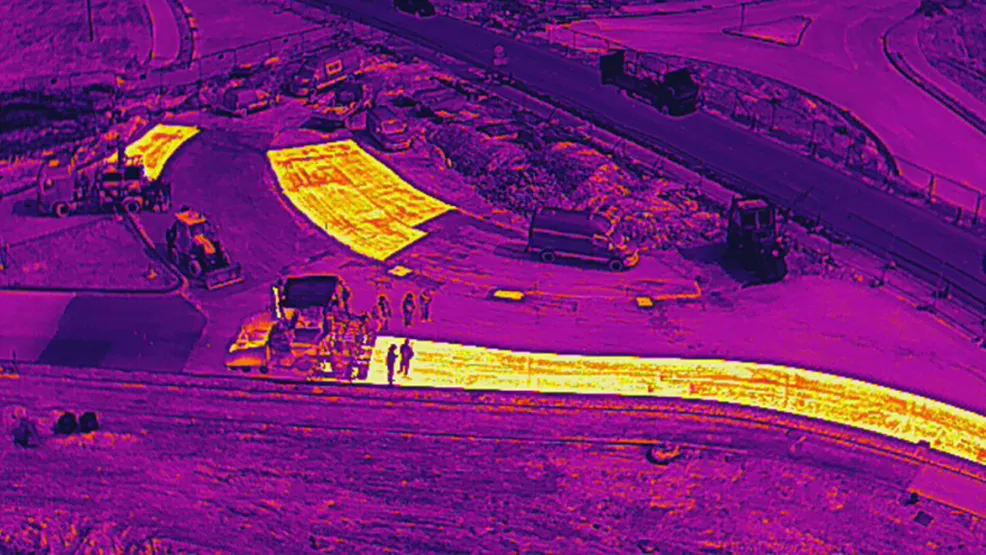

In collaboration with National Highways and AE Yates, Aggregate Industries has provided its brand-new SuperLow-Carbon biogenic asphalt for improvement works on the A590 in Ulverston – a £9.5m National Highways scheme.

The Brief

National Highways is delivering the A590 Cross-A-Moor project to reduce congestion and improve safety in Ulverston, Cumbria. The scheme includes the construction of a new roundabout, as well as brand new link roads, which will connect into the existing local road network. There will also be several environmental improvements including a new wetland area to ease flooding in Swarthmoor, and enhancements to biodiversity by planting a variety of species including native hedgerow.

Ensuring its road scheme demonstrates sustainable credentials to match the focus on environmental improvements in the area and National Highways’ plan to achieve net zero by 2030, a low carbon solution was required for this project.

As a key A-road through the town, National Highways also required a product that offered quick and easy application.

The Solution

Aggregate Industries had previously collaborated with National Highways and AE Yates on its nearby A590 Brettargh Holt scheme, where it provided its Foamix® low-carbon solution. Continuously seeking to raise the bar as it journeys towards its net zero targets, the partners selected SuperLow Carbon for the Cross-A-Moor project.

SuperLow is the UK’s first commercially available biogenic asphalt and has been developed in partnership with Shell Bitumen as a pioneering product for more sustainable pavement projects.

SuperLow-Carbon uses Low Carbon Bitumen in a unique formula that utilises improved production processes and alternative energy sources to lower its embodied carbon footprint. It includes a biogenic material that effectively locks CO 2 within the asphalt rather than releasing it back into the atmosphere.

SuperLow-Carbon is a warm-mix asphalt product, which means it requires lower energy to produce than its hot-mix equivalent without compromising on performance. Production at a lower temperature also reduces nuisance fuming, odour and steam at the project site, which in turn lowers burn risk, improves visibility and provides better working conditions for operatives.

In addition, lower asphalt temperatures during production reduces binder ageing and the product remains highly compactable for longer – allowing more time for full compaction, delivering enhanced performance and durability, and ultimately life-expectancy. It also reaches trafficking temperatures much quicker than hot mix products, allowing for earlier reopening of carriageways to the travelling public, resulting in less disruption and reduced build costs.

Neil Leake, National Technical Manager at Aggregate Industries, said: “We were delighted that National Highways selected SuperLow-Carbon for its A590 Cross-A-Moor project – marking the first installation of this product since it launched earlier this year.

“National Highways has a clear agenda to reduce carbon on all its schemes, and Aggregate Industries consistently provides new low-carbon solutions, enabling us to frequently work in partnership. SuperLow-Carbon really is the next generation of asphalt and sustainable paving products, and we can’t wait to see it contracted on many more projects in the future.”

Stephan Mason at National Highways, adds: “Having worked with Aggregate Industries on a number of projects in the past, including our recent A590 Brettargh scheme, we know they are always able to deliver on innovative, sustainable products and unrivalled customer service. This project in Ulverston is in a stunning, green part of the country, and thus a low-carbon asphalt solution was obvious for the scheme.

“SuperLow-Carbon demonstrates great innovation, with a low-carbon binder successfully delivering a CO 2 reduction in the base elements of the scheme. We look forward to working with Aggregate Industries again in the future, as it continues to lead the way in sustainable applications and supporting National Highways as it accelerates towards its net zero target.”

Sven Till at AE Yates, comments: “We have a great working relationship with Aggregate Industries and have shared many successes on reducing carbon in previous schemes. Aggregate Industries are a much-valued strategic partner to our business, as we all have our sights on achieving net zero carbon by 2030.”

Find out more about the National Highways A590 Cross-a-Moor Junction Improvement Scheme

- Millbrook Road West resurfaced with low carbon SuperLow asphalt

- Aggregate Industries supports in creating the UK’s first ‘clean air’ substation

- Aggregate Industries offers green solution to A46 Warwick Bypass project

- Aggregate Industries’ roofing creates natural aesthetics for eco-friendly supermarket - Case Study

- Poundland distribution centre, Harlow

Project Details

-

Location

A590 in Ulverston

-

Sector

Roads

-

Client

National Highways

-

Product Used

SuperLow-Carbon Asphalt

-

Other Information

- Project value £9.5million +

- Environmental improvements include new wetland area and increased biodiversity

- Find out more about this scheme on the National Highways website

National Highways has a clear agenda to reduce carbon on all its schemes, and Aggregate Industries consistently provides new low-carbon solutions, enabling us to frequently work in partnership. SuperLow-Carbon really is the next generation of asphalt and sustainable paving products, and we can’t wait to see it contracted on many more projects in the future.

SuperLow-Carbon, is the first commercially available asphalt that uses a biogenic material within the bitumen. This effectively locks carbon within the asphalt rather than releasing it back into the atmosphere. Providing a sustainable asphalt solution.